Building high-end and affordable noise barriers to block traffic noise.

Highway to low-carbon Silence.

Extrusion is the production process used, based on recycled PVC compound. Low melting temperatures minimize C02 emission.

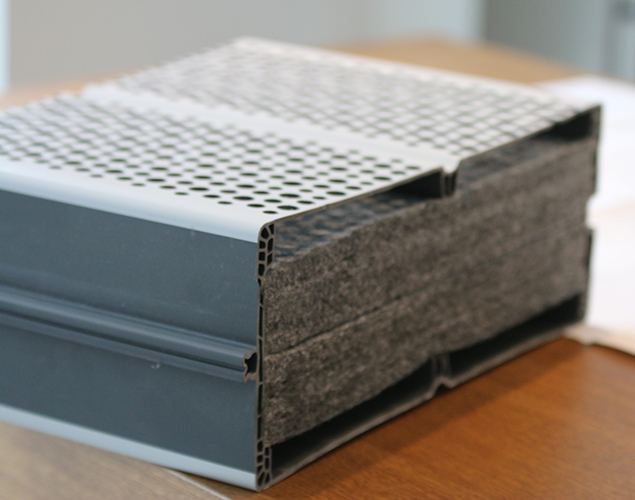

PVC coming from post-consumer and post-production waste starts a new life cycle. PVC can be recycled up to 7 times without any loss of mechanical performance. Extrusion requires very low melting temperatures compared to aluminium or any other metal, furthermore contributing to a minimum of CO2 emission during the production proces. The panel is made of recycled PVC compound (85%). The skin is made of virgin PVC compound (15%), mass colored and very UV-resistant.

Sound absorbing polyester mats made of recycled plastic bottles (PET) are inserted inside of the panel

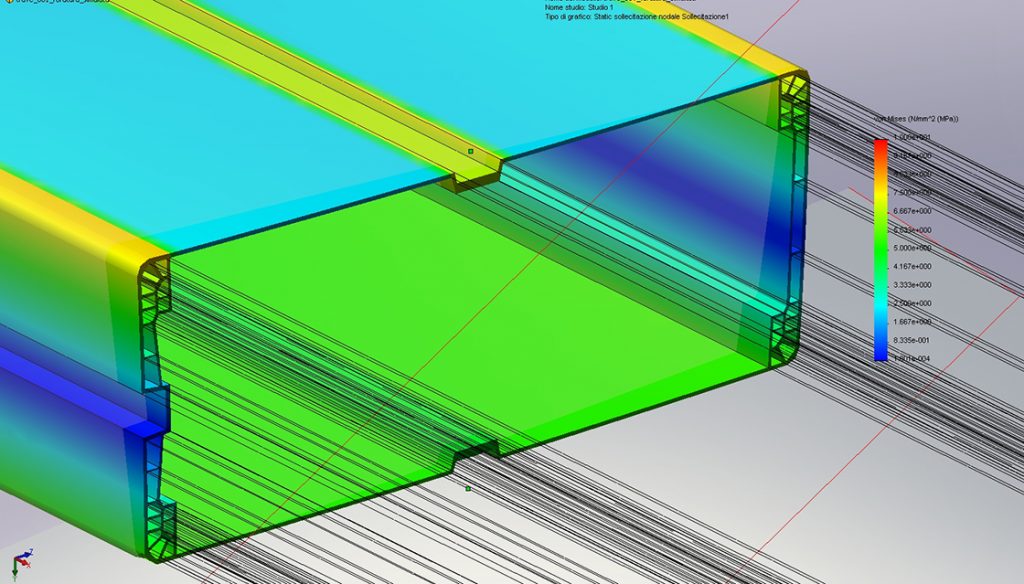

A smart panel geometry adds mechanical strength to a surprisingly thin shell allowing the panel to resist the severest dynamic and static loads, furthermore contributing to a sustainable acoustic solution.

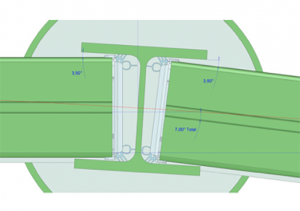

The panel is equipped with soundproof end caps on both ends of the panel, allowing a fast installation and keeping execution times to a minimum, without any risk for acoustic leaks.

Polyester fiber mats are known for excellent sound-absorbing, hydrophobic properties and come in various densities to satisfy all acoustic needs.

LE DIFESE® panels can be repaired on site: special pads are ‘ironed’ into the skin. Thanks to the dense and smooth surface, the panel is easy to clean (anti graffiti) and requires low maintenance. A thin external oxide film developed over time protects the panels surface ever more.

The skin is simultaneously co-extruded with the core (co-ex) and therefore mass colored: No need for any polluting coating process, contributing to even more sustainability.

The color chart presents up 10 standard colors, pastel colors and easy on the eye.

It is possible to combine LE DIFESE® panels with transparent sheets or add waterprints like wood for a more natural design.